p ă n – ŏ p t ĭk:

Taking in all aspects in a single view.

Our experience in the worldwide marketplace aids our clients in refining their products or developing new products. We have the expertise to make a concept a reality.

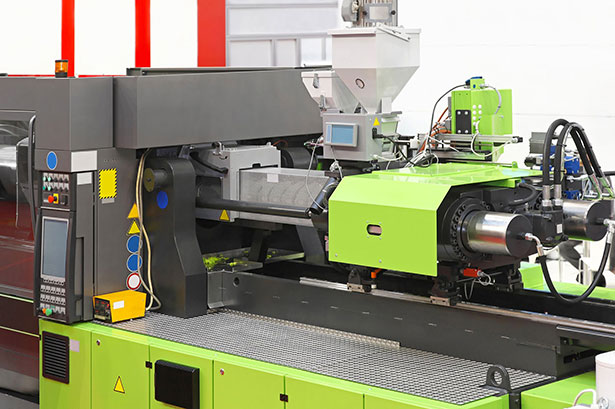

When bringing products to market it is important to take into account all of regulatory and compliance aspects. At Panoptik Compliance Solutions we do just that, we take into account all regulatory design considerations including EMC, Electrical and Machinery Safety, Reliability and Hazardous Locations.

Making sure your product or machinery is safe and that you can obtain the required agency or country certification marks is no easy feat.

First of all, not only are there numerous standards or directives within each industry, but these standards vary also between countries. You can take your product directly to the agencies, but this can be frustrating and a lengthy process. Agencies, by definition and by their accreditation, cannot provide you, as a customer, any design or certification assistance.

This is where the experts of PANOPTiK Compliance Solutions come into play.

Above all, we don’t want you to face these challenges alone. First, we want to get involved early and determine required the agency or country marking’s, applicable standards and compliance design strategy for your product. Secondly, as our experts work in many industries including Information Technology Equipment (ITE), Industrial, Test and Measurement, Machinery and Medical, we have a wealth of expertise to utilize. Since these industries have different requirements and emphasis, we differentiate what your product needs to succeed. As an example, a common area for us to start is by the development of a Risk Assessment and Hazard Analysis. This document determines any potential risks or hazards. It provides the mean to mitigate them by design, testing, warnings or protective tools and materials. One of our final evaluations is to look at installation and user procedures. In less complicated products this may just be a compliance plan.

Thirdly, It may be your desire to take an existing product into a new application/use, industry or country. Our experts can review your existing product or machine to the latest standards and provide you with what we call a "Gap Analysis." Essentially, the gap analysis or findings report allows you to address any short comings in your product, manuals or labeling before getting into the costing agency process.